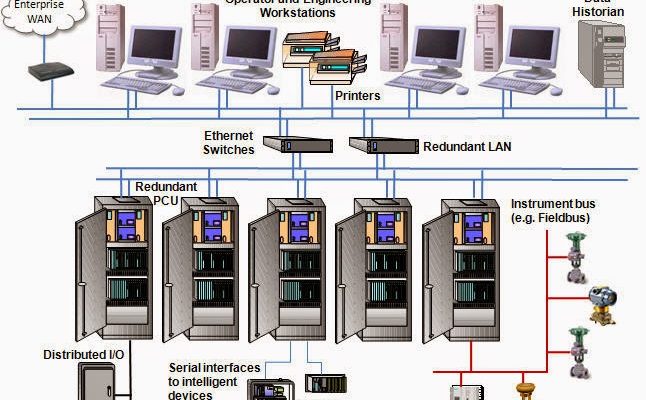

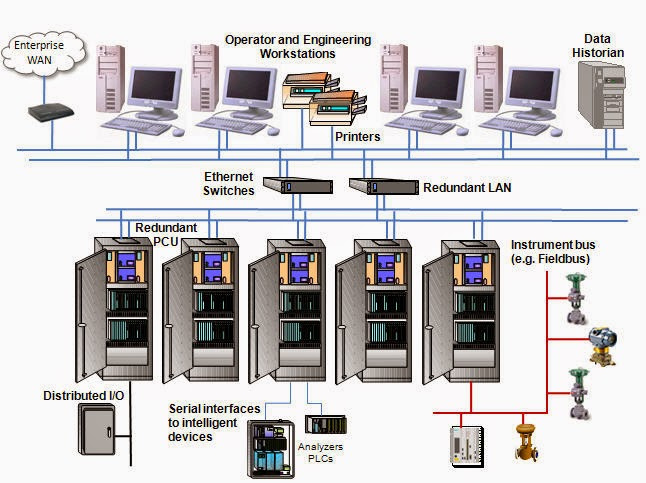

Components of DCS:

Operator console

Operator console

This tool is similar to a computer monitor. Used to provide feedback information about what is being done or done in the factory, besides that it can also display commands given to the control system. Also through this console, operators give orders to instruments in the field.

Engineering Console

These are stations for technicians used to configure the system and also implement control algorithms

History Module

This tool is similar to a hard drive on a computer. This tool is used to store DC configurations and also the configuration of all points in the factory. This tool can also be used to store graphics files displayed on the console and many systems are currently able to store factory operational data.

Data Historian

Usually in the form of software used to store process variables, set points and output values. This software has a high scan rate capability compared to the History Module.

Control Modules

This is like the brain of DCS 29. This is where control functions are executed, such as PID control, benchmarking control, ratio control, simple arithmetic operations and dynamic compensation. At present there are more sophisticated control module equipment with wider capabilities

I / O

This section is used to handle input and output from DCS. The input and output can be analog, can also be digital. Digital input / output such as ON / OFF or Start / Stop signals. Most of the controlled process and output measurements are analogous.

Interface DCS:

Human – Machine Interface

- Interface between DCS and Operator

- Centralized monitoring of the plant

- Presents the current plant information to the operator using the graphical user interface

- Translate operator instructions to the engine

- Enables operators to carry out operations, development, maintenance and troubleshooting

Engineering Interface:

- Interface between DCS and Engineer

- Enables the construction of DCS system and software maintenance

- Engineering Development Station

Interface to Other Systems

- Computer Interface Supervisory

Connect DCS to supervisory computer, transmit control data and receive the command supervisory operation and optimal settings.

- Control Sub-system interface

Connect DCS to other types of instruments such as PLCs, composition analyzers to integrate plant operations, etc.

Process Interface

- Interface between DCS and plant (field instruments)

- The Control Station receives a measurement signal from the sensor and performs a control calculation according to the set-point price deviation

- The output signal is sent to the final control element to take compensation action